How Do Batteries Work

As aspiring electricians, understanding the rudimentary components of electrical systems is an indispensable part of our career trajectory. One such component that continues to rear its head in our everyday life, is the humble battery. A battery, in the simplest terms, is a device that stores chemical energy and converts it into electrical energy when conductors connect to its terminals. It is the power behind anything portable in our lives, from our smartphones to cars. This article serves as an elementary guide on the basic makeup of a battery and the science behind its operation.

Components of a Battery

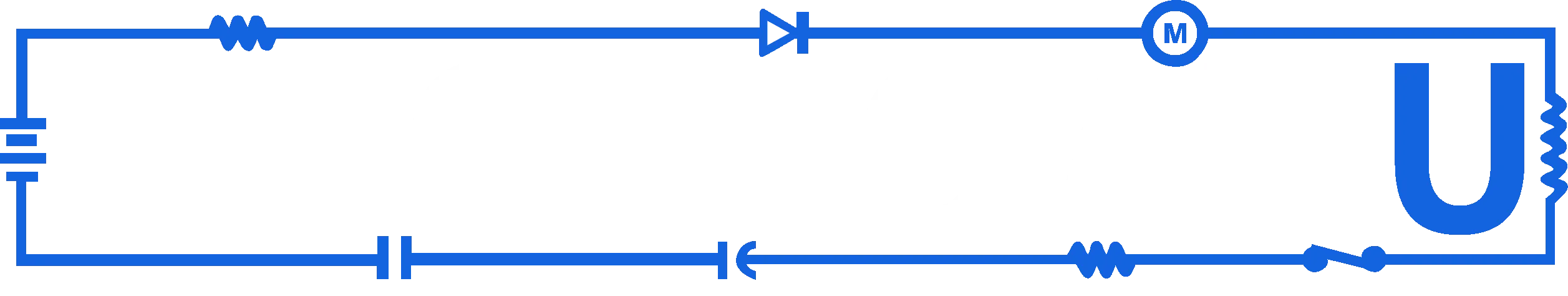

A battery’s design and function are more complex than what meets the eye. It comprises multiple key components, each playing a significant role in the overall performance of the battery.

The Anode and Cathode

At the heart of every battery are two electrodes: the anode and the cathode. In essence, these are the places where the chemical reactions occur. The anode, often referred to as the negative electrode, is where the oxidation reaction takes place. The cathode, also known as the positive electrode, is where the reduction reaction occurs. These complementary reactions are essential for the generation of an electric current.

At the anode, oxidation (loss of electrons) occurs, releasing electrons into the external circuit. This is typically where lithium ions, for instance, might give up electrons. The cathode, on the other hand, undergoes reduction (gain of electrons), accepting electrons from the external circuit. In lithium-ion batteries, for example, the cathode would be where lithium ions are incorporated into the cathode material during discharge.

Electrolyte

The electrolyte serves as the facilitator for the transfer of ions between the anode and the cathode. An electrolyte is a substance that produces an electrically conducting solution when dissolved in a polar solvent, such as water. It is a medium that contains ions, which can be either positively charged (cations) or negatively charged (anions). These ions move freely within the electrolyte, allowing for the flow of charge that produces electricity. The electrolyte, usually a liquid or gel containing mobile ions, plays a critical role in battery efficiency. It must efficiently conduct ions and block electrons to prevent internal short circuits. Its composition can significantly influence the battery’s performance, safety, and temperature stability.

Separators

While it’s important that the anode, cathode, and electrolyte interact, it’s equally vital to prevent a direct electrical connection between the anode and cathode. This is where separators come into play. Separators are thin sheets of insulating material that keep the two electrodes apart. Which prevents short circuits while allowing ions to pass through.

Source – https://cdn.britannica.com/

Modern battery separators are engineered to offer high ionic conductivity, minimal electrical conductivity, and robust mechanical properties. They are often porous films made from materials like polyethylene or polypropylene, which apart from preventing contact between the electrodes, also shut down the battery under high heat conditions as a safety feature.

How Batteries Work

Now that we understand the primary components of a battery let’s examine the process that leads to the generation of electric current.

- When a battery connects to an external circuit (like when you turn on your flashlight), a chemical reaction occurs at the anode. This results in the production of electrons. We call this reaction oxidation. The electrolyte blocks the electrons, forcing them to travel through the external circuit to the cathode and create an electrical current.

- Simultaneously, at the cathode, another chemical reaction takes place, which absorbs these electrons. Which we call this process reduction. The electrolyte facilitates the flow of ions between the anode and cathode, maintaining a balance of charge within the battery.

- The battery continues to produce electricity until one or both of the chemicals involved in the reactions are depleted.

- Rechargeable batteries can reverse this process. When an external power source is applied, the anode and cathode are forced to switch roles. The anode becomes the site of reduction, and the cathode becomes the site of oxidation. This process replenishes the chemical compositions at both electrodes. Restoring the difference of potential between them; preparing them for the next discharge cycle.

Source – https://www.flickr.com/

Batteries in Series and Parallel Configurations

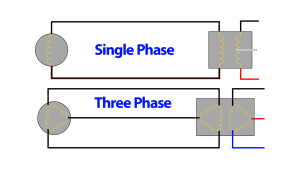

Batteries in Series

When batteries are connected in series, the positive terminal of one battery is connected to the negative terminal of the next battery. This setup increases the total voltage of the battery system while keeping the amperage (current capacity) constant. The voltage of each battery is added together. This enhances the overall output voltage, which is crucial for applications requiring a higher voltage than what a single battery can deliver.

- Example: If three 12-volt batteries each with a capacity of 100 amp-hours are connected in series, the total output becomes 36 volts (12V + 12V + 12V) while the amp-hour rating remains 100 amp-hours.

This configuration is commonly used in devices that require a higher operational voltage. Such as in some electric vehicles or in power backup systems where higher voltages are necessary for efficient power transmission.

Batteries in Parallel

Connecting batteries in parallel involves linking all positive terminals to one another and all negative terminals to one another. This configuration maintains the voltage level of a single battery but increases the total capacity (amp-hour rating) and the maximum current output (amperage) of the array. Essentially, the capacity of the batteries is summed up, allowing for longer usage and greater current draw, which is ideal for applications requiring high energy storage.

- Example: If three 12-volt batteries each with a capacity of 100 amp-hours are connected in parallel, the total output remains at 12 volts, but the capacity increases to 300 amp-hours (100Ah + 100Ah + 100Ah).

Parallel connections are often utilized in systems where longevity and higher current demand are crucial. Such as in RVs, boats, and renewable energy storage systems, where prolonged energy availability is necessary.

Impact on Cranking Amps in Vehicles

In automotive applications, especially in starting vehicles, batteries often need to deliver a high current for a short duration to turn the engine. This is measured in cranking amps (CA) or cold cranking amps (CCA). When “jumping” a battery, conductive cables are connected “red to red, black to black”, establishing a parallel connection between the two. This keeps the voltage the same between the two batteries, however adds capacity to the system, allowing enough energy to kick over the starter and start the engine. When the engine is started the alternator begins recharging the battery, and the cables can be disconnected.

Connecting batteries in parallel can increase the available cranking amps, enabling more power to start larger engines or providing reliability in cold weather when battery performance typically declines.

- Cranking Amps: This refers to the number of amps a battery can deliver at 32 degrees Fahrenheit (0 degrees Celsius) for 30 seconds while maintaining a voltage of at least 7.2 volts for a 12-volt battery.

- Cold Cranking Amps: This measures the battery’s ability to start an engine in cold temperatures specifically at 0 degrees Fahrenheit (-17.8 degrees Celsius), under the same conditions as CA.

Considerations for Capacity and Lifespan

While configuring batteries in series or parallel can meet specific voltage and capacity requirements, it’s essential to ensure that the batteries match in terms of capacity, state of charge, and health to prevent imbalance. Imbalances can lead to reduced efficiency, potential overcharging, or discharging, which might prematurely degrade the battery’s lifespan.

Types of Batteries and Their Applications

Primary and Secondary Batteries

Primary batteries are disposable, designed for one-time use before they are depleted and cannot be recharged effectively. Examples include the alkaline batteries commonly used in TV remotes and smoke detectors. Secondary batteries, or rechargeable batteries, like those found in smartphones and electric vehicles, can be charged and discharged multiple times.

Lead-Acid Batteries

These are one of the oldest types of rechargeable batteries, commonly used in automotive starters. They operate on the principle that lead and lead oxide, in an acidic electrolyte, react to produce lead sulfate and electrons.

Lithium-Ion Batteries

Lithium-ion batteries are prevalent in portable electronics, construction tools, and electric vehicles due to their high energy density and ability to handle numerous recharge cycles. They work by moving lithium ions between the anode and cathode through a lithium salt in an organic solvent electrolyte. Want to explore different types of batteries? Check out “The Diverse Universe of Batteries: Exploring Different Types”

Source https://www.milwaukeetool.com/

Future Technologies

Emerging battery technologies, such as solid-state batteries, aim to replace liquid electrolytes with solid conductors to improve safety and energy density. Other innovations include lithium-sulfur and flow batteries, which promise higher capacities and longer lifespans.

Conclusion

Understanding the complexities of battery technology not only enhances your capabilities as an electrician but also prepares you to engage with advanced technologies and troubleshoot more effectively. As the world increasingly moves towards energy storage solutions for a range of applications—from mobile devices to grid storage—the role of skilled electricians in maintaining, designing, and innovating these systems will only grow. Stay curious and informed, and you will find yourself at the forefront of this dynamic field.