Differences in single phase vs three phase power

As an electrician, understanding the intricacies of power systems is crucial for both installation and troubleshooting. One of the fundamental concepts you’ll encounter is the difference between single-phase and three-phase power. Additionally, the evolution from the old two-phase systems to modern three-phase systems in the United States is a significant milestone worth exploring.

Understanding Single-Phase Power

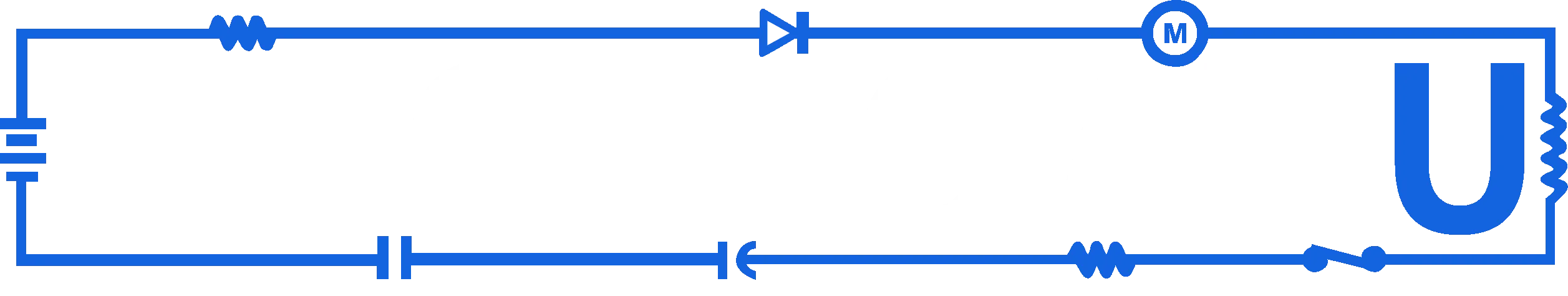

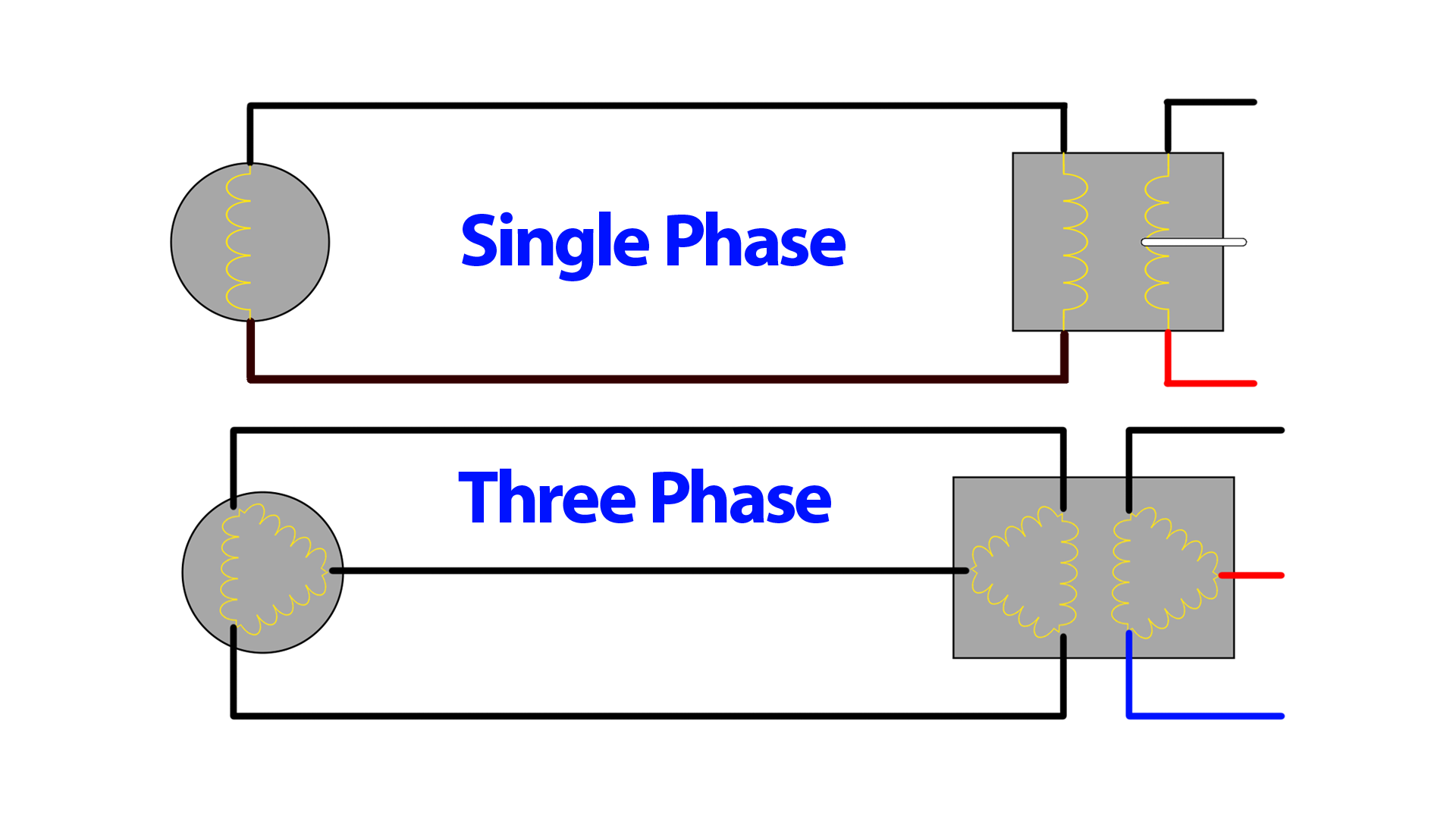

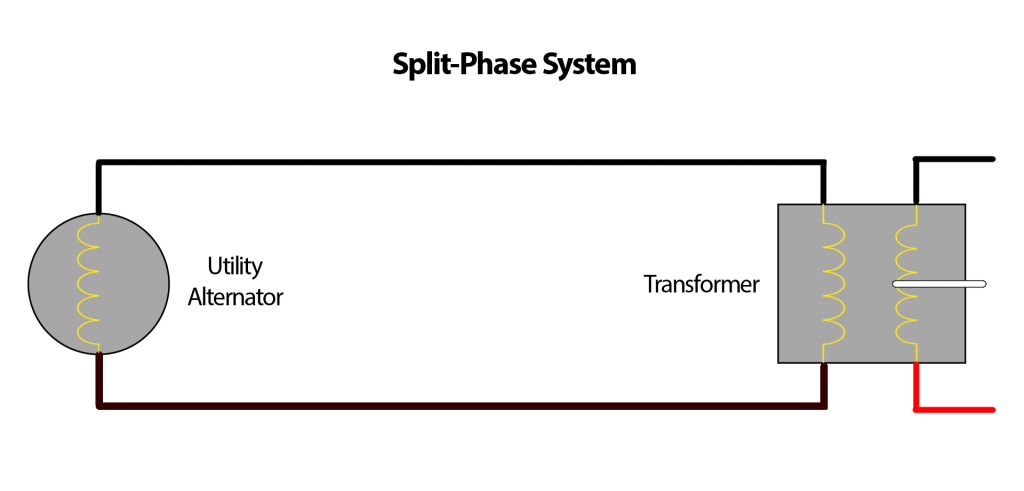

Single-phase power is the most common type of electrical power distribution for residential and light commercial applications. It utilizes a single conductor loop from the utility company’s alternator where AC power is being generated, out to some endpoint, and back to the utility alternator. This single “loop” is referred to as a “phase”. In reality, this loop is cut at the far end and a transformer is stuck between the two sides of the conductor, allowing a customer to access the system and draw power down to a building or structure. Because of this “break” in the wire, we consider the phase as having two wires, one from the alternator, and one back to the alternator. In truth, however it’s just one long wire forming a large loop.

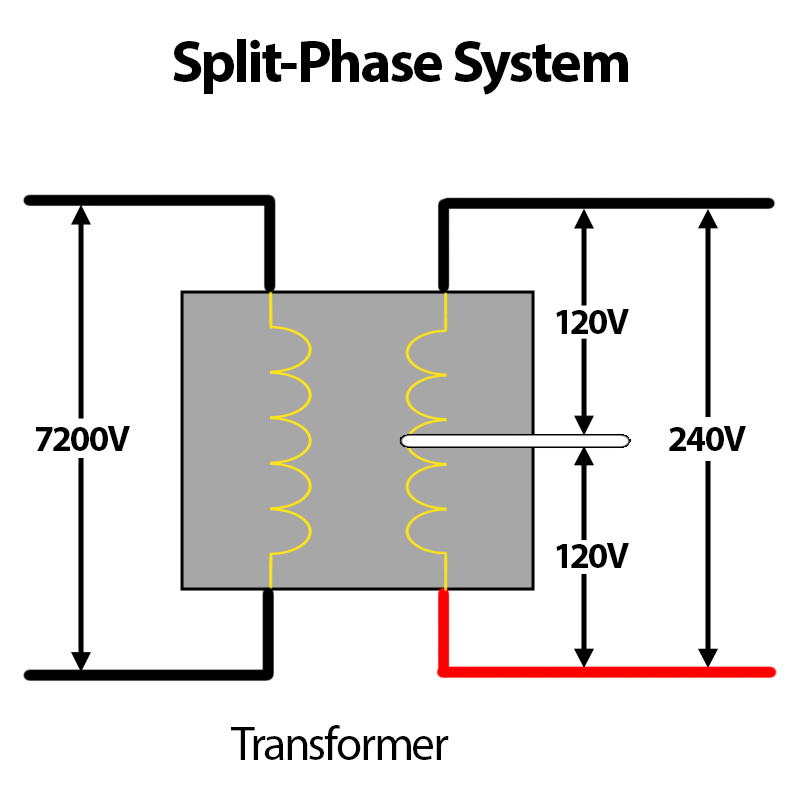

A term often used to describe single phase, is “split phase”, where the loop is split in half, allowing two smaller phases, or loops inside of it. For example, coming from the transformer at the street, a black and a red conductor are run down to a building to provide a 240 Volt loop. Within the transformer we tap onto the midpoint of the transformer winding with a white conductor (neutral) and run that down to the building as well. This neutral “splits” the 240 volts into two 120 volt circuits, while still maintaining an overall 240 volt system as well.

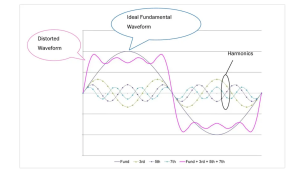

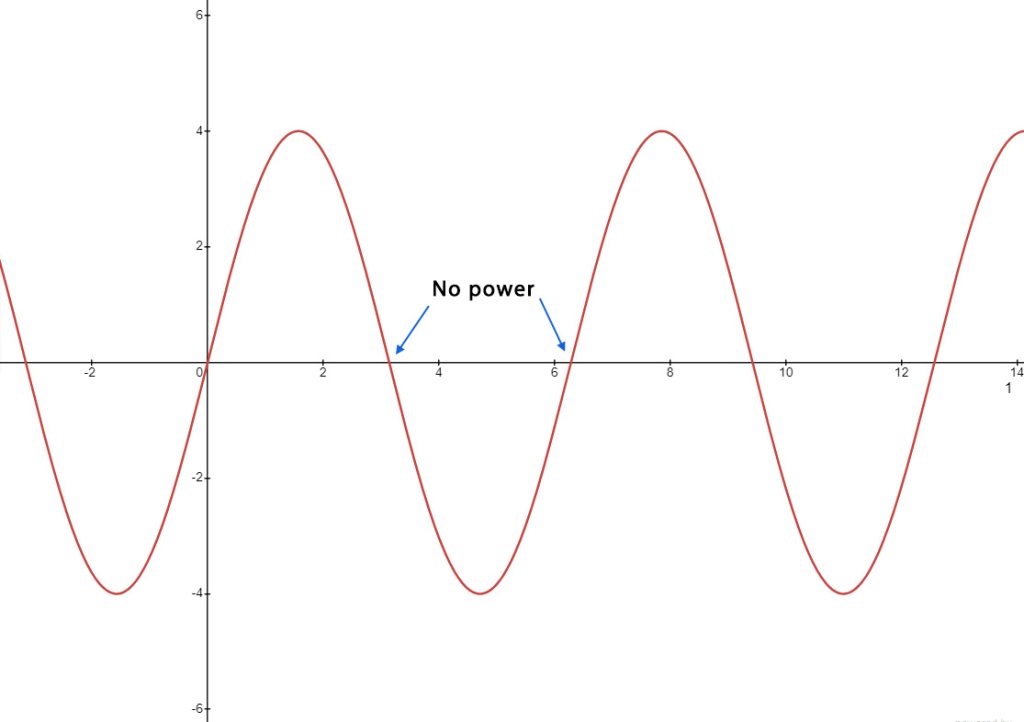

The voltage in a single-phase system oscillates sinusoidally, reaching zero volts twice per cycle. Because of this, single-phase systems pulse on and off very rapidly making them somewhat inefficient compared to DC or three-phase electrical systems.

Characteristics

- Voltage Waveform: Single-phase power consists of a single sinusoidal voltage waveform that alternates between positive and negative polarities. This creates a smooth and continuous flow of current which oscillates back and forth rapidly, rather than in a constant direction as with direct current (DC).

- Frequency: The standard frequency for single-phase power is 60 Hz (60 cycles/oscillations per second) in North America and 50 Hz in most other parts of the world.

- Voltage Levels: Common voltage levels for single-phase power are 120V and 240V in North America, and 230V in many other regions.

Considerations for Electricians

- Suitable Loads: Ideal for lighting, heating, and small appliances.

- Motor Performance: Single-phase motors have less starting torque and are less efficient than three-phase motors.

- Load Balancing: Limited options for balancing loads across phases.

- Efficiency: Less efficient for transmitting power over long distances.

Applications

Single-phase power is widely used in residential settings and small businesses. It powers everyday household appliances, lighting, and small electrical devices. Examples of single-phase power applications include:

- Home Appliances: Refrigerators, washing machines, air conditioners, and microwaves.

- Lighting: Indoor and outdoor lighting fixtures.

- Small Office Equipment: Computers, printers, and copiers.

- HVAC Systems: Heating, ventilation, and air conditioning units in homes and small buildings.

Delving into Three-Phase Power

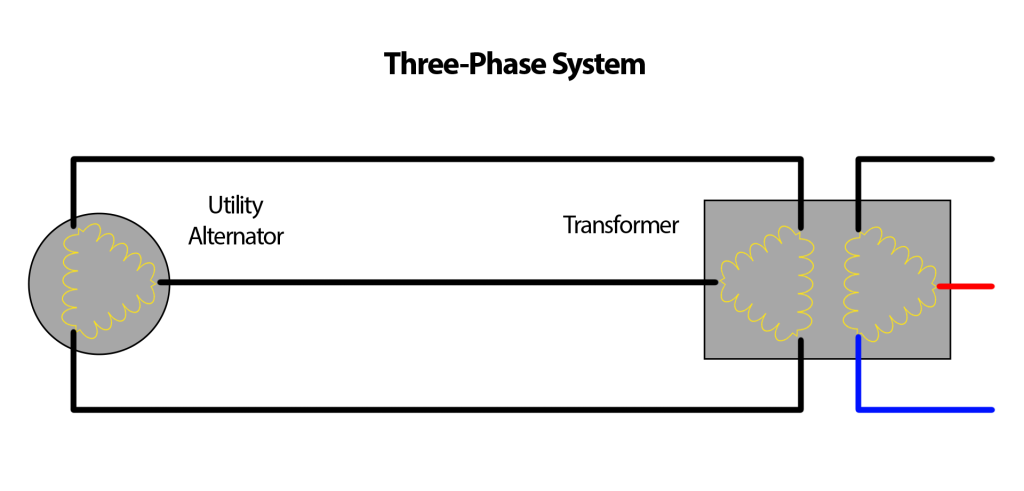

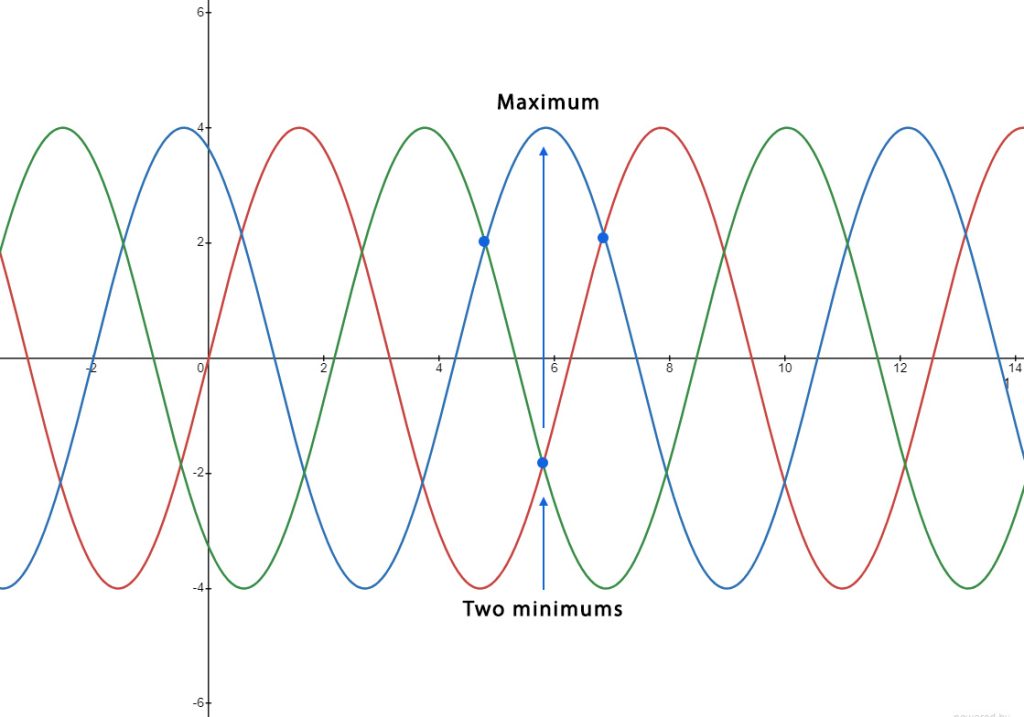

Three-phase power is predominantly used in industrial and commercial settings where large amounts of power are required to run heavy loads such as lighting and machinery. It consists of three “hot” wires, each carrying an alternating current of the same frequency and voltage amplitude, but with a 120-degree phase shift between them. This configuration provides a constant power flow, making it ideal for heavy machinery and equipment.

Three phase systems are composed of three loops, or phases, from the utility alternator out to a building or load. A transformer is terminated at the end of these loops allowing a customer or structure to tap into the transformer and access three phase power near the transformer. With three phase, in most U.S. systems, we have a black, a red, and a blue “phase” conductor. These conductors represent a polarity, relative to the other two conductors – similar to how we use black and red in single-phase systems to identify what side of the loop we’re on.

Rather than having periods of zero volts within the circuit, as found in single phase systems, three phase systems never have a time where current flow stops or “pulses.” Instead while one phase is at it’s maximum magnitude, the other two phases are at some lesser value; each of which exchanging this relationship continuously 60 times a second. This makes three phase a fairly “constant” power system which is far more efficient, especially when driving machines. Three phase is a modern type of polyphase design which replaced the older two-phase systems in use in the early 1900s in the U.S.

Characteristics

- Voltage Waveforms: Three-phase power consists of three sinusoidal voltage waveforms, each separated by 120 degrees. This phase separation results in a more consistent and balanced power supply which does not pulse.

- Frequency: Similar to single-phase power, the standard frequency for three-phase power is 60 Hz in North America and 50 Hz in most other parts of the world.

- Voltage Levels: Common voltage levels for three-phase power include 208V, 240V, 400V, and 480V, depending on the region and application.

Considerations for Electricians

- Complex Installation: Requires a deeper understanding of phasor diagrams and phase relationships.

- Safety Precautions: Higher voltages and currents necessitate stringent safety measures.

- Equipment Compatibility: Ensuring that equipment is rated for three-phase power.

Applications

Three-phase power is widely used in industrial and large commercial settings where high power demand and efficiency are critical. Examples of three-phase power applications include:

- Industrial Machinery: Motors, pumps, and heavy machinery used in manufacturing and processing plants.

- Commercial Buildings: Large HVAC systems, elevators, and escalators.

- Power Transmission: High-voltage transmission lines that distribute electricity over long distances.

- Data Centers: Servers, cooling systems, and other high-demand equipment.

Comparing Single-Phase and Three-Phase Power

| Aspect | Single Phase | Three Phase |

|---|---|---|

| Number of Conductors | Two (Three if neutral present) | Three (Four if neutral present) |

| Voltage Peaks | Peaks twice per cycle | Peaks six times per cycle |

| Power Delivery | Pulsating, not constant | Constant, smoother delivery |

| Applications | Residential, light commercial | Industrial, heavy commercial |

| Motor Efficiency | Less efficient, less starting torque | More efficient, higher starting torque |

There are some key differences between single phase and three phase power that make one of them more or less useful in certain environments. There are also different configurations for both single-phase and three-phase that allow some interesting results. Not all three phase systems, for example, have the same voltage. There are systems which produce 240V while others allow for 208V; the difference being how they’re wired. The major differences between single and three phase are as follows:

Efficiency

- Single-Phase Power: Less efficient for high power loads due to the pulsating nature of the single voltage waveform. It can result in power losses and voltage drops over long distances.

- Three-Phase Power: More efficient for high power loads as the three-phase system provides a continuous power flow with less pulsation. This reduces power losses and maintains voltage levels more effectively.

Power Delivery

- Single-Phase Power: Suitable for low to moderate power demands, making it ideal for residential and light commercial applications.

- Three-Phase Power: Capable of delivering higher power levels, making it suitable for industrial and large commercial applications.

Motor Performance

- Single-Phase Motors: Typically used in small appliances and equipment. They have a simpler design but can experience torque pulsations, which can affect performance and efficiency.

- Three-Phase Motors: Commonly used in industrial applications. They provide smoother and more reliable operation with higher efficiency and better torque characteristics.

Wiring Complexity

- Single-Phase Wiring: Simpler wiring with typically two conductors (one hot and one neutral) or three conductors (two hots and one neutral) for 240V applications.

- Three-Phase Wiring: More complex wiring with typically four conductors (three hots and one neutral) or five conductors (three hots, one neutral, and one ground) depending on the configuration.

Historical Context: Two-Phase Wiring Systems

Before the widespread adoption of three-phase power, two-phase power systems were used in some regions. These systems provided an intermediate solution between single-phase and three-phase power.

Two-Phase Systems

- 3-Wire Two-Phase: Consisted of two hot wires and one neutral wire. The two hot wires carried voltage waveforms 90 degrees out of phase with each other.

- 4-Wire Two-Phase: Consisted of two pairs of hot wires, with each pair carrying voltage waveforms 90 degrees out of phase with the other pair. This system provided more balanced power distribution compared to the 3-wire configuration.

Applications and Limitations

Two-phase systems were used for both residential and industrial applications. However, they had limitations in terms of efficiency and complexity compared to three-phase systems. The transition to three-phase power provided a more efficient and scalable solution for power distribution, leading to the gradual phase-out of two-phase systems.

Conclusion

Understanding the differences between single-phase and three-phase power is essential for making informed decisions about electrical power distribution. Single-phase power is well-suited for residential and light commercial applications, providing a simple and reliable power source. In contrast, three-phase power offers significant advantages for industrial and large commercial applications, including improved efficiency, higher power capacity, and smoother motor operation. While two-phase systems were once used, the transition to three-phase power has provided a more effective and scalable solution for modern power distribution needs.