120 vs 208 vs 240 vs 277 vs 480: Why all the Voltages?

Often apprentices get into the trade and see a plethora of different equipment rated at different voltages, and it can be pretty confusing until they start to see commonality in where they’re used. For instance, apprentices often as what is the difference between 208 vs 240 vs 277 volt systems? They seem so close together, couldn’t they all be combined as just one voltage? The answer is, absolutely not.

Comparing Voltages

In the electrical industry, various standard voltages are used across residential, commercial, and industrial settings, each selected based on specific application requirements and efficiency considerations. Understanding these voltages and their typical uses is important for electricians to ensure safe and effective electrical system design and maintenance.

To start lets briefly cover the most common voltages seen in the electrical industry today:

5 Volts (5V)

- Application: Commonly used in electronics and communication systems.

- Usage: Powers devices like USB-powered peripherals, microcontrollers, and various sensors.

- Configuration: Typically supplied by DC power sources such as batteries or regulated power supplies.

12 Volts (12V)

- Application: Widely used in low-voltage lighting.

- Usage: Powers LED strip lights, fixtures and landscape lighting, audio systems, and auxiliary equipment.

- Configuration: Provided by 12V batteries or DC power supplies; also common in low-voltage residential lighting systems.

16 Volts (16V)

- Application: Commonly used in doorbell/chime wiring.

- Usage: Powers doorbell transformer/chime/pushbutton systems.

- Configuration: Supplied by 120V AC, then transformed to 16VAC for use across a home.

24 Volts (24V)

- Application: Standard in industrial control systems and heavy-duty low-voltage lighting.

- Usage: Powers control relays, sensors, and industrial automation equipment.

- Configuration: Derived from series-connected 12V batteries or dedicated 24V power supplies.

120 Volts

- Application: Standard household voltage in North America.

- Usage: Powers most residential lighting, receptacles, and small appliances.

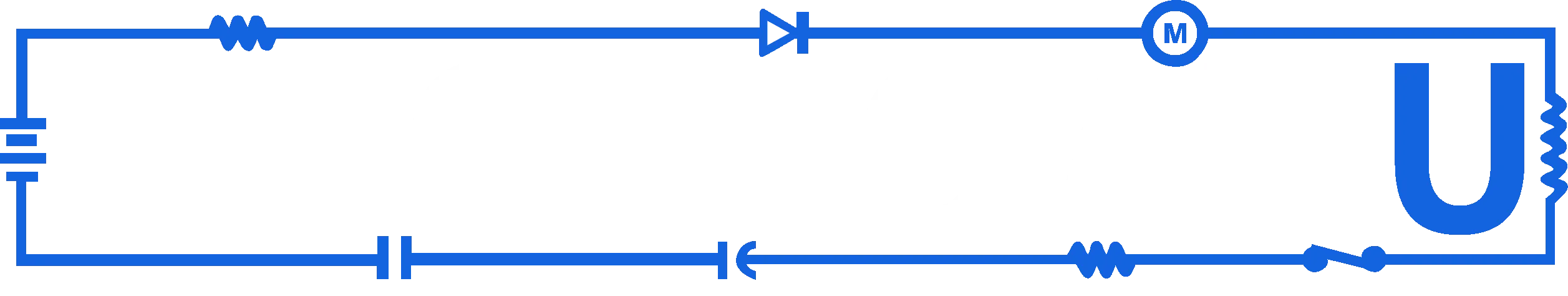

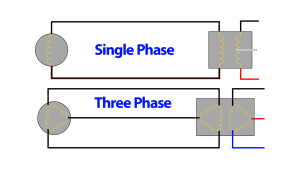

- Configuration: Derived from a single-phase, split-phase system where a center-tapped transformer provides two 120V lines with a neutral.

208 Volts

- Application: Common in three-phase commercial and light industrial settings.

- Usage: Powers three-phase equipment such as motors and larger HVAC systems.

- Configuration: Obtained from a three-phase Wye (star) configuration, providing 208V between any two phases and 120V from any phase to neutral.

240 Volts

- Application: Used in both residential and industrial environments.

- Usage: Powers heavy-duty appliances like electric ovens, dryers, and air conditioners as well as industrial motors.

- Configuration: In residential settings, achieved through a split-phase system combining two 120V lines to provide 240V. In industrial settings, can be derived from a three-phase Delta configuration.

277 Volts

- Application: Primarily in commercial and industrial lighting systems.

- Usage: Efficiently powers high-intensity discharge (HID) and fluorescent lighting.

- Configuration: Sourced from a 480V three-phase Wye system, providing 277V from any phase to neutral. This is comparable to 120V setups, just at an even higher potential for heavier-duty applications.

347 Volts

- Application: Common in Canadian commercial and industrial lighting systems.

- Usage: Powers lighting systems similar to 277V applications but at a higher voltage.

- Configuration: Derived from a 600V three-phase Wye system, providing 347V from any phase to neutral.

480 Volts

- Application: Standard for industrial equipment and large commercial buildings.

- Usage: Powers large motors, heavy machinery, and substantial HVAC systems.

- Configuration: Typically provided through a three-phase Wye system, offering 480V between phases and 277V from phase to neutral.

600 Volts

- Application: Common in Canadian industrial settings.

- Usage: Powers heavy machinery and large motors.

- Configuration: Delivered via a three-phase Wye system, providing 600V between phases and 347V from phase to neutral.

208 vs 240 vs 277

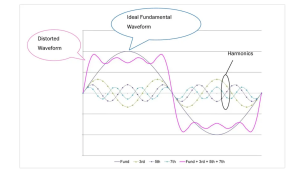

The confusion often lies in the understanding of 208 vs 250 vs 277 when dealing with voltages, most-often in three-phase environments. Because these numbers are so close together, many apprentices think they mean the same thing. However, their uses are distinct and must be treated as such.

In three phase systems buildings are delivered a certain power system. When the utility company provides power to property, they will drop a transformer on that property. This transformer can be wired in certain ways to get certain voltages out that the customer may utilize on that property. Some properties have transformers wired internally in a way which produces a 208V output, while others are wired a certain way to produce 240V. There is a reason a property may want the higher voltage option vs the lower, and this is generally based on the use of the property. Many office buildings require 208V while many manufacturing facilities may need 240V. So the entire property is at the voltage delivered based on the use.

This is also true for 480/277v systems which are just higher voltage versions of 240/120V systems. Both of these voltage systems can be delivered in three-phase or single-phase, however homes only require 240/120V whereas large facilities often need higher voltage (pressure) in the system for all of the lighting and equipment they have. So whereas 208V and 240V are voltages between two hots (ungrounded conductors), 277V is voltage between a hot and neutral (just like 120V is)

Why So Many Voltages?

The diversity in voltage levels arises from the need to balance efficiency, safety, and equipment requirements. First of all there are many different machines and equipment which are designed to handle certain voltages. Secondly our utility system is set up with specific voltages so everything down the line is built to match it.

If you think of voltage as “electrical pressure” you can see why some things need lower pressure than others in an electrical system. A doorbell, for example to energize a chime in your home does not require the same force to accomplish it’s job as a 50 HP motor used in an industrial logging facility to cut massive trees into lumber. Even higher voltages (500,000V for example) allow for the transmission of more power with reduced current, minimizing energy losses over long distances.

And lastly, regulatory standards and safety considerations dictate appropriate voltage levels for various applications to ensure user safety and system reliability. Tools, safety gear, and who has access to touch parts of electrical systems often dictate what materials and voltage classes are allowed in certain environments. For example, having a lamp in a house with 120V at the light socket is not as hazardous as a 2,000V switchgear in an industrial facility. For this reason voltage classes are limited depending on who has access to the system, and what types of equipment are installed.