In this article we will continue our discussion of sizing generators from our last article “Types of Generators and How to Select One” If you have not read that article we recommend reading it as it gives a great precursor into the various types of generators used in residential and commercial/industrial settings. Moving forward we will discuss in-depth sizing techniques for generators. We will also go over some 2023 National Electrical Code considerations associated with sizing. If you’re here just to use the calculator we’ve put it at the top of the article for your convenience:

Generator Selection Calculator

Load Information

Fire Pump Load

Results

Total kVA:

Recommended kVA (with 1.25 safety factor):

What does the NEC say about sizing generators?

The National Electrical Code doesn’t necessary provide a calculation for sizing generators, however there are some important sections to refer to: Articles 700.4, 701.4, and 702.4 (life safety, legally required standby, and optional standby) state that the system shall have adequate capacity in accordance with Article 220, or another approved method:

700.4(A) Capacity.

“An emergency system shall have adequate capacity in accordance with Parts I through IV of Article 220 or by another approved method. The system capacity shall be sufficient for the rapid load changes and transient power and energy requirements associated with any expected loads.”

701.4(B) Capacity.

“A legally required standby system shall have adequate capacity in accordance with Parts I through IV of Article 220 or by another approved method. The system capacity shall be sufficient for the rapid load changes and transient power and energy requirements associated with any expected loads.”

702.4(A) System Capacity.

(1) Manual and Nonautomatic Load Connection.

“If the connection of load is manual or nonautomatic, an optional standby system shall have adequate capacity and rating for the supply of all equipment intended to be operated at one time. The user of the optional standby system shall be permitted to select the load connected to the system.”

(2) Automatic Load Connection.

“If the connection of load is automatic, an optional standby system shall comply with 702.4(A)(2)(a) or (A)(2)(b) in accordance with Parts I through IV of Article 220 or by another approved method.

(a) Full Load. The standby source shall be capable of supplying the full load that is automatically connected.

(b) Energy Management System (EMS). Where a system is employed in accordance with 750.30 that will automatically manage the connected load, the standby source shall have a capacity sufficient to supply the maximum load that will be connected by the EMS.”

Essentially, the NEC is telling us how to calculate the loads connected to the generator. It does not specifically state how much load a particular generator can handle. The responsibility for sizing the generator system properly lies with the designer of the generator system or perhaps the generator manufacturer.

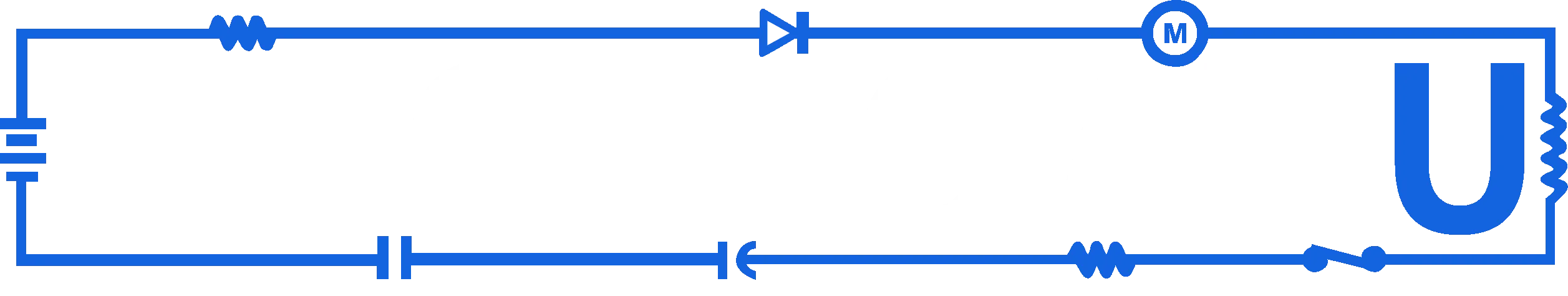

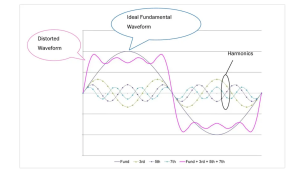

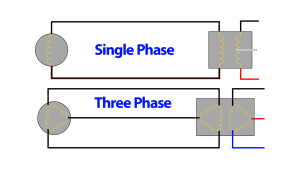

Sizing Generators Using Power Factor

In the previous article, we discussed that power factor represents the ratio of real power absorbed by the load (Watts) to the apparent power flowing in the circuit (Volt-Amps). When looking at a generator, we need to consider two different power factors. One is the power factor of the alternator on the generator, itself. This is usually 0.8 or 80% (sometimes 1, or 100 percent, on smaller single-phase generators). The power factor of the load supplied by the generator also requires consideration. Power factor can be either leading or lagging. Lagging power factor, when current lags behind the voltage, is caused by inductive loads such as motors or transformers. Leading power factor, when the current leads, is caused by capacitive loads such as battery chargers, capacitor banks, and other electronics. In most buildings, the majority of the onsite loads will be of the lagging type.

Sizing Generator Example

The concept of apparent power (Volt-Amps, or VA) versus real power (watts, or W) is a crucial one to grasp for generator sizing. When calculating loads, it is important to make sure we are working in volt amps, or VA, rather than watts. Working in watts does not always consider power factor, which could lead to an undersized generator. To do this we use the following formulas:

(Used when kW is unknown)

(Used when kW and PF are known)

Now let’s look at an example calculation.

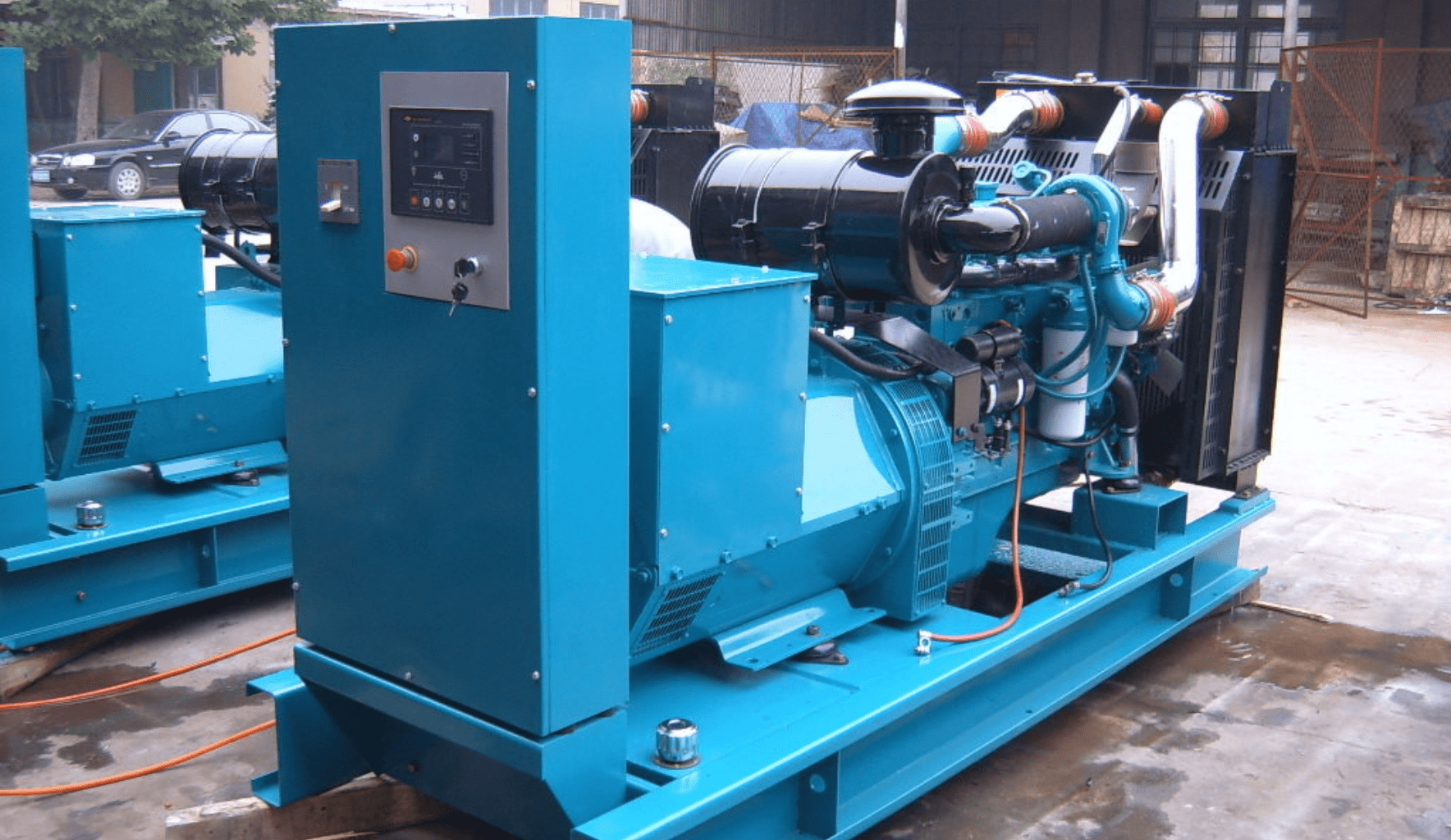

EXAMPLE: A customer has requested for a new generator to go into their brand new 20 story office building. They only want to have one generator for all the loads required in the building. The generator must be a three phase 480V generator. Natural gas and diesel are both options.

Load breakdown:

- 100kW @ 0.9PF of life safety loads (emergency lights, fire alarm etc).

- 50 HP fire pump (65A, 480V, 3 phase, @ 0.8PF).

- 500kW of optional standby load from tenants @ 0.9PF (lights, receptacles and computer loads)

- 200kW of legally required standby @ 0.9PF (elevators, stair pressurization fans etc).

Step 1: Convert all loads to volt amps

Life Safety loads (100kW @ 0.9PF):

Fire Pump:

Optional Standby load (500kW @ 0.9PF):

Legally Required Standby load (200kW @ 0.9PF):

Total sum of all loads (in kVA):

Step 2: Choose a generator size

Since the calculated load is 932kVA, we want to make sure we have enough buffer room for future expansion as well as motor startup. The recommended safety factor is about 25%.

Generators come in manufactured sizes so in this situation we would most likely consider a 1,250kVA generator with an 80% Power Factor. Remember that we are looking at the Volt-Amp values, even though most generator manufacturers provide only the Watt or kW rating. Working in VA, we are 100% certain that this generator will work.

Step 3: Consider generator fuel source

Since this application has life safety loads connected to the generator, the fuel source becomes an important consideration. Per Article 700.12 of the NEC: “Current supply shall be such that, in the event of failure of the normal supply to, or within, the building or group of buildings concerned, emergency lighting, emergency power, or both shall be available within the time required for the application but not to exceed 10 seconds.”

This code section requires that life safety loads are up and running within ten seconds of a power failure. That means the generator needs to be able to start up and get to a steady state extremely quickly. As mentioned in our previous article, one of the downfalls of natural gas generators is a slow start up time at the larger sizes. Since this is a 1,000kW unit, a diesel generator will most likely be the best choice. However, recently some generator manufacturers are providing generators of up to 1,000kW that are ten-second capable, while running on 100 percent natural gas.

Helpful Tips and Tricks

There will be many instances where the power factor is unknown. A helpful tip is to use 0.9, or 90PF, on most modern buildings or new construction buildings. The reason for this is that the biggest contributing factor to power factor in a building is usually large, inefficient motors. Most modern-day motors are highly efficient and are controlled with variable frequency drives or even soft-start motor starters. This is common when installing new mechanical equipment such as chillers, pumps, or air handlers. Also, many LED drives and computers have active power factor correction and/or operate at 0.9 or great power factor. 0.8 can be considered for older buildings with outdated equipment and motors.

Load shedding is also something that can be an option if increasing a generator size is not possible. Load shedding means that not all loads are running simultaneously – those that are unused are ‘shed’ or turned off, meaning that a smaller generator can be used. For example, when a fire pump is active on generator power, optional standby loads can be shed as the building will be evacuated at that point and the standby loads will not be needed. Both loads would not run at the same time, so we would only consider the larger of the two loads when sizing the generator.

Conclusion

Understanding the significance of power factor is crucial as it directly impacts both real power and apparent power within a system. Proficiency in converting between watts and volt amps, and vice versa, holds fundamental importance for both professionals and enthusiasts. This knowledge becomes indispensable when determining the appropriate generator size to match the specific energy demands of an application. Equally important is the careful consideration of the fuel type for the generator. This decision can significantly affect operational costs, reliability, and environmental impact, depending on the intended application. Armed with these insights, individuals can confidently make informed decisions while selecting or recommending a generator, ensuring it not only meets but surpasses expectations.