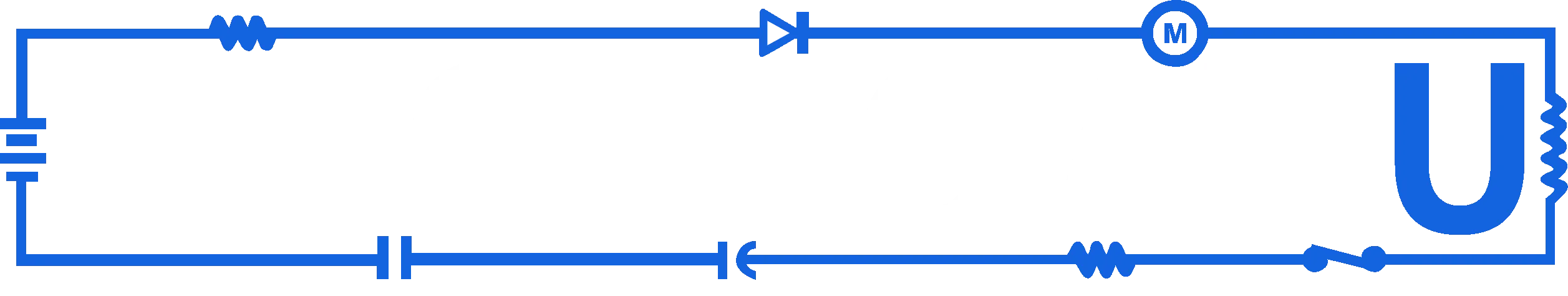

Nonmetallic-sheathed (NM) cable is one of the most commonly used wiring methods in residential electrical systems. Users appreciate its versatility, color coding system, price point, and ease of installation. Article 334 of the 2023 National Electrical Code (NEC) provides specific guidelines on how to secure and support NM cable to prevent mechanical damage and ensure long-term safety and functionality. Adhering to these regulations is not just a best practice, it’s a requirement for passing electrical inspections and maintaining the integrity of a home’s electrical system.

NM cable, often referred to by its popular brand name, Romex, consists of two or more insulated conductors, often with a bare equipment grounding conductor, all enclosed in a non-metallic protective outer sheath. Often electricians call this outer sheath “insulation” which is not correct, as it has no electrical insulating properties like those around the individual conductors. It is simply a protective barrier which encases the conductors as a complete cable assembly. This type of cable is popular in residential construction because of its ease of use, affordability, and protective design. There are a few varieties of NM cable in existence so understanding the specific type of NM cable and its applications is crucial for compliance with the NEC and safe installation.

Source – https://www.amazon.com/

Types of NM Cable

The different types – NM, NM-B, and NMC – reflect variations in materials and specifications that make them suitable for different environmental conditions and applications. Here’s a breakdown of each type:

NM Cable

NM stands for nonmetallic sheathed cable. Some people use NMC for the abbreviation, but this confuses some as there is actually a different NMC cable which we will get to below. NM is the general category for this type of electrical cable. Originally, NM cables used a rubberized fabric or varnished cambric for insulation of individual conductors and a braided cloth jacket as the sheathing. Installers no longer use this older type of NM cable in new installations. This is due to advancements in cable technology and changes in safety codes.

Source – https://alphabuildinginspections.com/

NM-B Cable

NM-B stands for nonmetallic sheathed type-B cable. The ‘B’ indicates that the cable uses 90°C-rated PVC insulation around each conductor, rather than previous 60°C variant. In the 2023 National Electrical Code (NEC), Article 334.80 states “The ampacity of NM cable shall not exceed that of a 60°C (140°F) rated conductor” even though NM-B is a 90°C conductor. It continues with “The 90°C (194°F) rating shall be permitted to be used for ampacity adjustment and correction calculations, provided the final calculated ampacity does not exceed that of a 60°C (140°F) rated conductor.”

As with normal NM cable, the outer sheathing encasing the inner insulated conductors is not insulation. Rather it is just protective sheathing for the inner conductors. NM-B cable is the most common type of NM cable today, especially in residential building wiring. Compared to earlier NM cables, NM-B uses a thermoplastic outers sheath. It offers improved durability and resistance to moisture and heat. Although it still does not have a rating for wet conditions.

Source – https://www.amazon.com/

NMC Cable

NMC, an older style of nonmetallic sheathed cable, suits both wet and damp locations. The ‘C’ signifies that the cable is corrosion-resistant. People often confuse NMC with ‘Non Metallic Cable,’ but this is not accurate. NMC is a specific type of NM cable. The distinction matters because Article 334 of the 2023 NEC specifically calls it out several times.

NMC cables use an outer jacket that has a higher resistance to moisture, oils, and other solvents. Making it suitable for use in basements, some types of outdoor applications, and other wet or damp environments. We can also use this type of cable in both exposed and concealed locations making it more versatile than NM and NM-B due to its enhanced environmental resistance. 2023 NEC Article 334.116 states “The overall covering shall be flame retardant, moisture resistant, fungus resistant, and corrosion resistant.”

Today, because of its regular availability, installers more commonly use Type UF in applications where they would otherwise use NMC

Requirements for Securing and Supporting NM Cable (NEC 334.30)

The NEC requires installers to secure and support NM cable adequately to prevent sagging and damage. According to NEC 334.30, installers must secure and support NM cable at intervals not exceeding 4 1/2 feet and within 12 inches of every cable entry into enclosures such as boxes, cabinets, or fittings. You may staple cables closer together than this, but not further apart. This rule ensures that the cable does not put strain on terminations and joints. Thus reducing the risk of electrical failures or hazards.

Additionally, in horizontal runs through holes and notches, 334.30(A) considers conductors supported and secured where the support of these holes or notches does not exceed the same 4 1/2 foot and 12 inch intervals:

“334.30(A) Horizontal Runs Through Holes and Notches.

In other than vertical runs, cables installed in accordance with 300.4 shall be considered to be supported and secured where such support does not exceed 1.4-m (4 1⁄2-ft) intervals and the nonmetallic-sheathed cable is securely fastened in place by an approved means within 300 mm (12 in.) of each box, cabinet, conduit body, or other nonmetallic-sheathed cable termination.”

334.30(B) extends this to unsupported cables by stating “Nonmetallic-sheathed cable shall be permitted to be unsupported where cable is:

- fished between access points through concealed spaces in finished buildings or structures and supporting is impracticable.

- not more than 1.4 m (4 1⁄2 ft) from the last point of cable support to the point of connection to a luminaire or other piece of electrical equipment and the cable and point of connection are within an accessible ceiling in one-, two-, or multifamily dwellings.”

This same excerpt mentions a list of materials allowed for the means of securement, and only one of them is required to be listed. Not only do the cable and fittings have to be listed, per 334.6, but 334.30 states that “nonmetallic-sheathed cable must be supported and secured by staples, cable ties listed and identified for securement and support, straps, hangers, or similar fittings…” Manufacturers must list and identify cable ties specifically for the securement and support of cables. This requirement ensures that the products used for securing and supporting cables meet certain safety standards and are suitable for the purpose; minimizing the risk of damage to the cable and maintaining system integrity.

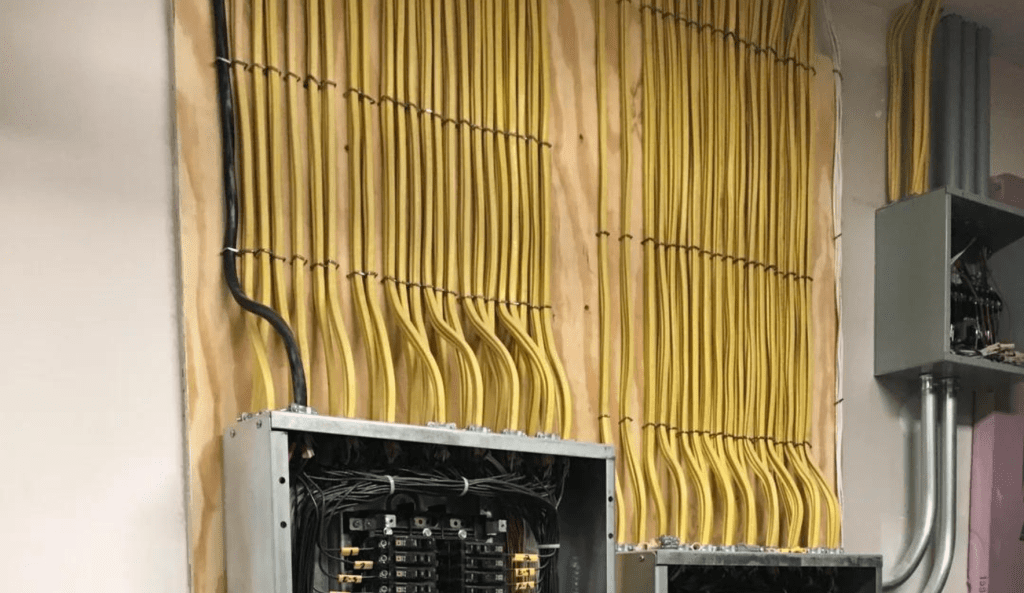

Source – https://www.reddit.com

Additionally this section mentions “the cable length between the cable entry and the closest cable support shall not exceed 18 in.” and that “flat cables shall not be stapled on edge.” Sometimes electricians leave “service loops” at boxes or light fixtures. So, if you need to move a box, there is some slack available for adjustments. However over the years, some people have gone far overboard with the amount of slack available. While they may have stapled within 12 inches of a recessed can housing, they may have coiled up 3 feet of wire between the securement and the box. This 18-inch length requirement addresses the amount of cable allowed within the 12-inch distance requirement.

Installers must staple flat cables, like 12/2 and 14/2 NM-B, on edge to ensure that stapling does not crush the conductors together. The proper method of stapling is to lay the conductor flat on the stud, then add another conductor flat on top of it. Then stapling the two together under the same staple. (See image above)

Special Considerations

When running cable through joists or studs, it is crucial to protect it from potential damage by drilling centered and smooth-edged holes. The NEC also requires that installers place cables running parallel to framing members at least 1 1/4 inches from the nearest edge of the framing member to protect against nail or screw punctures. In instances where NM cable is installed through wood members and the 1 1/4 inches cannot be adhered to, article 300.4(A)(1) stipulates “…the cable or raceway shall be protected from penetration by screws or nails by a steel plate(s) or bushing(s) at least 1/16 in thick, and of appropriate length and width, installed to cover the area of the wiring.” This includes installing NM in notches in wood.

Source – https://diy.stackexchange.com/

We don’t frame some buildings out of wood studs, rather they may be steel studs. In these cases 300.4(B)(1) mentions “In both exposed and concealed locations where nonmetallic-sheathed cables pass through either factory- or field-punched, cut, or drilled slots or holes in metal members, the cable shall be protected by listed bushings or listed grommets covering all metal edges that are securely fastened in the opening prior to installation of the cable.”

Pre-planning is a practice most experienced electricians use, who have seen screws through enough conductors over the years to stay cautious. Avoiding running NM cable too close to floor/door/window trim as well as crown molding can reduce service calls and rerunning wire. Installations in environments such as attics where roofers can drive nails through conductors run too close to framing. 300.4(E) specifically calls out cables installed in or under metal-corrugated roof decking requiring not less than 1 1/2 inches of space measured from the lowest surface of the roof decking to the top of the cable. The exception to this is for corrugated roof decking covered with a minimum of 2 inches of concrete slab.

Source – https://modernize.com/

Another important consideration is the installation of multiple cables together in a bundle. 334.80 states “Where more than two NM cables containing two or more current-carrying conductors are installed, without maintaining spacing between the cables, through the same opening in wood framing that is to be sealed with thermal insulation, caulk, or sealing foam, the ampacity of each conductor shall be adjusted in accordance with Table 310.15(C)(1) and 310.14(A)(2), Exception, shall not apply. 310.15(C)(1) specifies that this applies when installers do not maintain spacing for cables installed continuously longer than 24 inches. This means we must derate these conductors as we would with multiple current carrying conductors pulled through a conduit.

Lastly, we need to take moisture seriously with NM cable. 334.12(B) states that installers must not use NM cables in wet or damp locations. Many people make the mistake of running NM in conduit underground, or in other wet locations, only to find the conductors damaged and corroded years down the line. Article 100 defines “Wet Locations” as any location:

- Unprotected and exposed to weather

- Subject to saturation with water and other liquids

- Underground

- In concrete slabs or masonry in direct contact with the earth

This includes the interior of a raceway in a wet location as well as raceways underground. In these situations we require a different conductor or cable type.

Conclusion

Understanding the rules for securing and supporting NM cable is crucial for any electrical installation. As part of a commitment to electrical safety, it is important for professionals to keep sharp on NEC updates and local amendments. Ensuring compliance not only promotes safety but also enhances the reliability and efficiency of the electrical installation. Check out the “Wiring With MC Cable: What You Can and Cannot Do” article next!

All references to the National Electrical Code, NEC, or NFPA are copyrights of the NFPA, these citations are owned by the National Fire Protection Agency and are only here for educational reference.