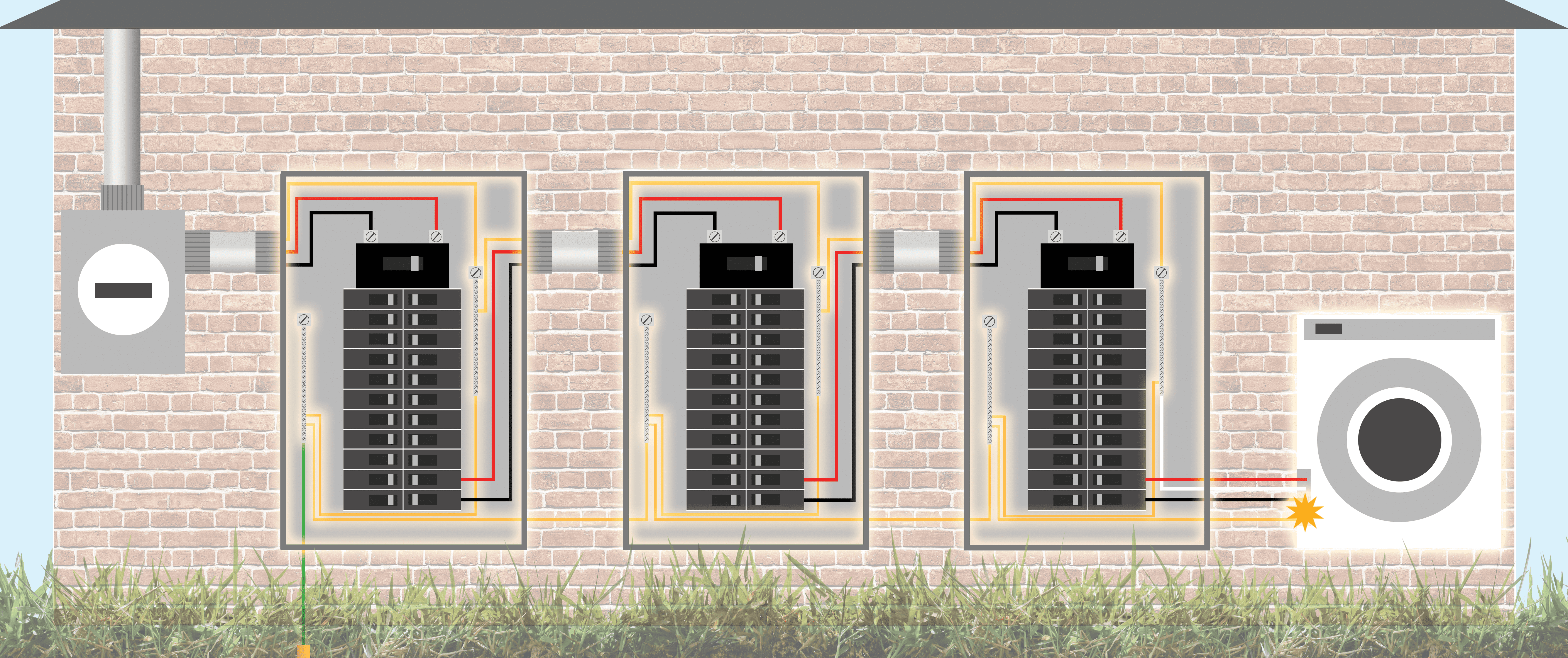

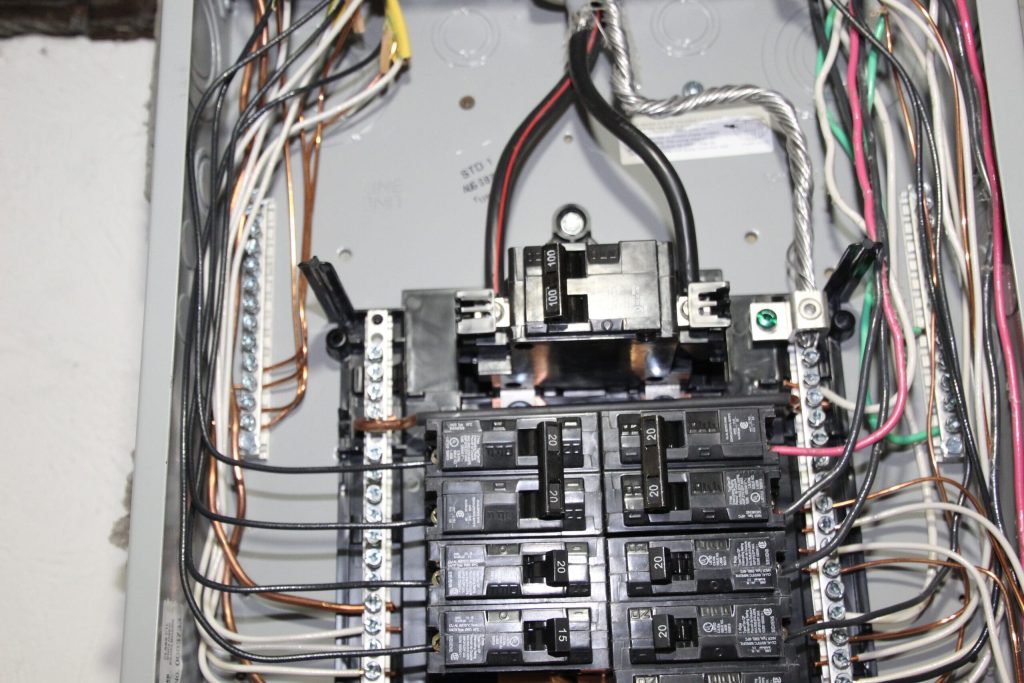

People often ask us about bonding. Specifically, why we require electricians to bond neutrals and grounds together at the service disconnect or panel. The next question is usually, “why do we only do it here and not also at sub-panels along the line?”. For example, the image below shows a subpanel with a green bonding screw on the neutral bus. This is a violation, as this is a subpanel. But why? These are valid questions. Once we come to an understanding it’ll be clear how to ground and bond moving forward.

Understanding Bonding and Grounding

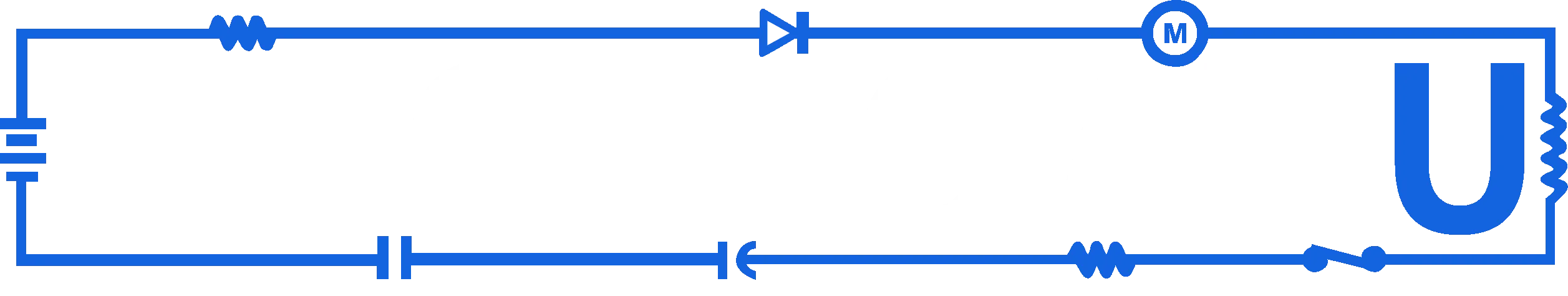

Before diving into the specifics of where bonding occurs, it’s essential to clarify what bonding and grounding are. As well as why they are critical components of electrical systems. Bonding refers to the practice of connecting electrical components together to establish electrical continuity and conductivity. Grounding involves connecting the electrical system to the earth. Which serves as a common reference point for electrical potential (voltage) throughout the system.

The primary purpose of bonding and grounding is to ensure safety by:

- Facilitating the safe path for the flow of fault currents back to the source during a short-circuit or ground-fault.

- Limiting the voltage imposed by lightning, line surges, or unintentional contact with higher voltage lines and stabilizing the voltage to earth during normal operation.

Source – https://global.discourse-cdn.com

The Role of the Service Panel

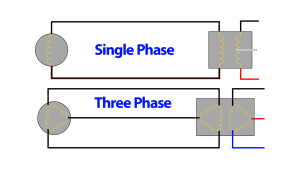

The service panel, often referred to as the main service panel, is the central point where the electrical supply enters a building from the utility source. This panel, typically fed from a nearby meter, houses the main breaker. Which serves as the primary shut-off point for the entire electrical system of a building. Not all services have main panels. However, rather many simply have a main disconnect which disconnects power to panels or equipment further down the line. Wherever the first means of disconnection are for the entire premises, is where the electrical service starts. As far as code is concerned, the electrical meter socket is not considered service equipment. Article 230.66 – 2023 NEC)

The NEC, in several places, mandates that the neutral (grounded conductor), the equipment ground (grounding conductor), and any main or system bonding jumpers must be bonded at this point, in grounded AC systems.

- 250.130(A) “The connection (of equipment grounding conductors – EGC’s) shall be made by bonding the EGC to the grounded service conductor (neutral) and the grounding electrode conductor (GEC).”

- 250.24(A): “A premises wiring system supplied by a grounded AC service shall have a grounding electrode conductor (GEC) connected to the grounded service conductor (neutral), at each service…”,(A)(1) “The grounding electrode conductor connection shall be made at any accessible point from the load end of the overhead service conductors, service drop, underground service conductors, or service lateral to the terminal or bus to which the grounded service conductor is connected at the service disconnecting means.”

- 250.25(C): “For a grounded system, an unspliced main bonding jumper shall be used to connect the equipment grounding conductor(s) and the service-disconnect enclosure to the grounded conductor within the enclosure for each service disconnect…”

- 250.24(E): “A grounding electrode conductor shall be used to connect the equipment grounding conductors, the service-equipment enclosures, and, if the system is grounded (has a neutral), the grounded service conductor to the grounding electrode(s) required…”

This bonding is crucial for several reasons:

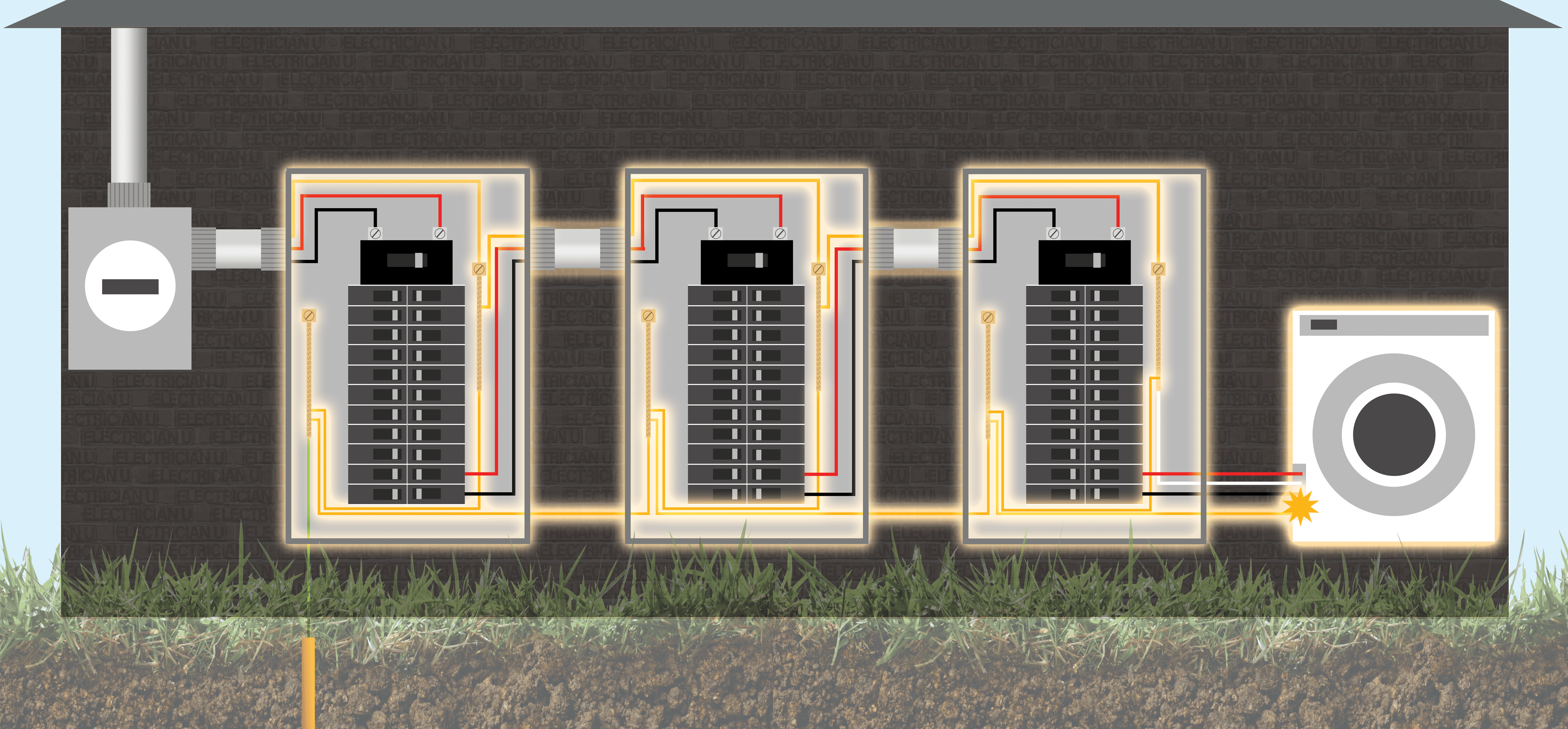

- Clearing Ground Faults: Bonding equipment grounding conductors to neutrals at the service panel creates a low-impedance path back to the source. In the event of a fault, such as an energized conductor touching a metal enclosure, the fault current follows the equipment grounding path back to the panel’s ground bus. When bonded to neutral, this fault current continues to travel through the service’s main grounded (neutral) conductor back to the utility transformer. Causing an immense amount of current flowing through the affected circuit, tripping the circuit’s breaker, and de-energizing the faulted circuit.

- Common Potential: By bonding the neutral and grounding electrode at the service panel, we ensure that the entire system has a reference point to earth. Effectively stabilizing voltage through the entire system. Not only on the premises, but along the entire distribution system and network. We bond all homes to common earth potential ensuring the entire system maintains stable potential. This strategy minimizes the risk of potential differences (voltage) between different points in the system. Which could lead to unexpected voltage fluctuations and electric shock hazards. This is critical because it ensures that, under normal operation conditions, there is no voltage difference between conductive parts that might touch simultaneously. Thereby enhancing the safety for inhabitants and service personnel alike.

Why Not Bond at Subpanels?

Subpanels are secondary circuit breaker panels that are fed from the main service panel and are typically used to distribute power to specific areas or provide support for a high demand of electricity away from the main panel. The reasons for not bonding neutral and ground in subpanels are for safety and functionality.

In the National Electrical Code, Article 250.6(A) mentions the term “objectionable current”, however without actually defining the term:

250.6 Objectionable Current. (A) Arrangement to Prevent Objectionable Current.

“The grounding and bonding of electrical systems, circuit conductors, surge arresters, surge-protective devices, and conductive normally non-current-carrying metal parts of equipment shall be installed and arranged in a manner that will prevent objectionable current.”

The NEC also goes on, in 250.6(C), to define what is NOT classified as objectionable current. “Currents resulting from abnormal conditions such as ground faults, and from currents resulting from required grounding and bonding connections shall not be classified as objectionable current…”

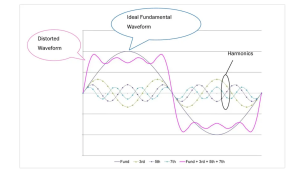

Objectionable Current is Continuous

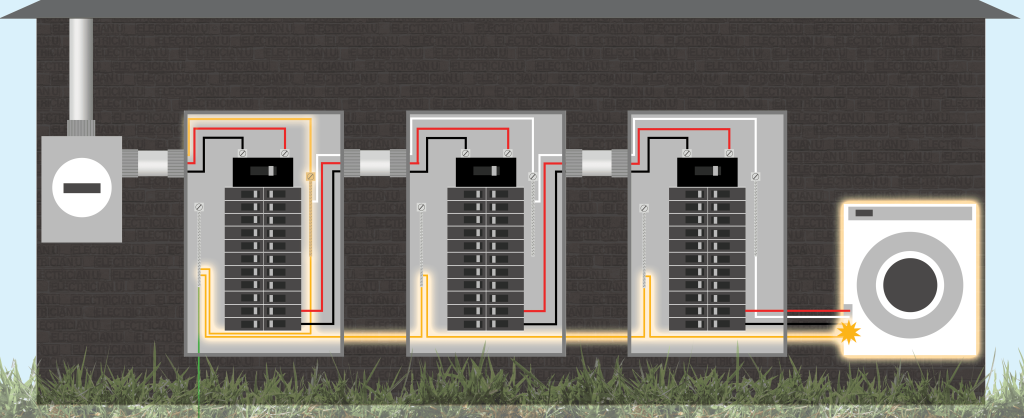

The concern, is continuous current using the wrong path. Specifically, a path a person could touch and get hurt or equipment could be damaged. If the neutral and ground were bonded at subpanels, it could create parallel paths for return current to flow back to the service panel. Utilizing the bare equipment grounding conductor as a path for neutral current. If continuous neutral current is flowing on metal enclosures, or bare conductors someone could touch them, resulting in serious injury.

Another benefit of separate bonding is in ensuring effective ground fault protection. Keeping the neutral and ground separate at subpanels ensures that any ground faults anywhere in the system will produce enough current to trip the circuit breaker effectively. Bonding at each subpanels could dilute the fault current through various metal, enclosures, and conductors and impede the reliability of protective devices. The reason code mentions “low-impedance fault current path” so often is to drive home the effectiveness of the fault-clearing system. Impedance (similar to resistance) is opposition to current; we don’t want opposition when we need a breaker to trip. We want as much current to flow instantaneously that a breaker is guaranteed to trip.

Conclusion

Bonding at the service panel and not at subpanels is a critical aspect of electrical safety. This practice prevents dangerous ground loops, ensures the effectiveness of ground fault protection systems, and aligns with established electrical codes. Understanding the rationale behind these wiring practices allows us to better appreciate the complexities of electrical safety and system design. By adhering to these standards, it ensures that electrical systems are not only effective. But that they also provide maximum safety against electrical faults and failures.

All references to the National Electrical Code, NEC, or NFPA are copyrights of the NFPA, these citations are owned by the National Fire Protection Agency and are only here for educational reference.